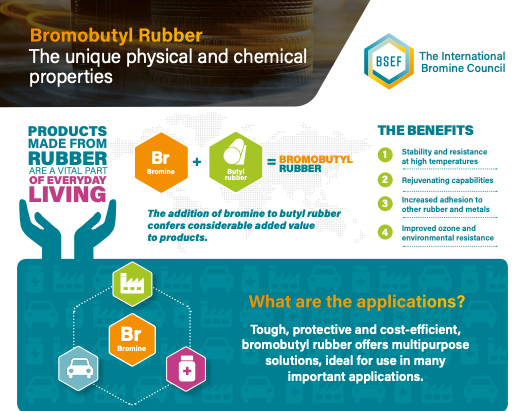

Bromobutyl rubber is derived from combining butyl rubber with bromine. Developed in the 1940s, the addition of bromine to butyl rubber gives considerable added value to the product. Most commonly used in the automotive industry, butyl rubber has considerable physical strength, low permeability, and is highly shock, weather and age resistant.

Rubber

The addition of bromine to rubber makes the material particularly suited for tyres, and medical stoppers

Besides the attributes associated with butyl rubber, bromobutyl rubber possesses other fundamental advantages including stability at high temperatures, rejuvenating capabilities, stronger resistance, increased adhesion to other rubbers and metals, and lastly, improved ozone and environmental resistance1.

did you know ?

Tyres

Tyres

In comparison to the formerly used tyres, contemporary radial tyres contain bromobutyl rubber that is found in its inner lining. This inner lining is used to hold the tyres’ air. Benefits in the use of bromobutyl rubber, include the tyre’s ability to self-seal with respect to small puncture holes, and improve its air retention performance and therefore the tyre’s durability.

In regards to air retention, the lining provides a barrier that prevents air from entering the tyre’s structure and degrading its rubber. Due to its polymer structure, a 100% bromobutyl polymer tyre provides the lowest air permeability rate. Ultimately, this ensures that the product life cycle of the tyre is longer, and contributes to the safety of motorists by avoiding tyre failure. An increase in a tyre’s longevity, requiring less tyre replacements also has an overall positive impact on the environment.

Medical Stoppers and membranes

Medical Stoppers and membranes

Due to their sealing abilities, bromobutyl rubber stoppers are used for sealing medicine vials and bottles in hospitals and laboratories for the safe and effective storage and application of drugs and for scientific research. Bromobutyl rubber has a number of different properties that makes it applicable for medical and scientific uses; for example, it is chemically inert, nonpolar and contains a low level of extractable impurities that could contaminate the drug over time2.

Another important property is that the rubber’s membrane rejuvenates when pierced with a needle. This process can be repeated a number of times, so that the stopper does not need to be changed after each use.

Conveyor belts

Conveyor belts

Heat resistant conveyor belts used in cement plants, foundries, heating and power stations, experience temperatures that can reach up to 400°C. In order to tolerate such extreme temperatures, conveyor belts made of bromobutyl rubber have been developed and refined over years. The conveyor belts are covered in bromobutyl rubber and act as a barrier to the source of heat. Apart from ensuring that the extreme conditions can be sustained, the cover also contributes to a longer operational lifespan as it protects the belt itself from the heat.

Windscreen wipers

Windscreen wipers

Properties such as resistance to weathering and temperature changes, make bromobutyl rubber appropriate for use in windscreen wipers as it adds to their durability.

Overview of advantages

Physical strength

Shock resistant

Low permeability

Age and weather resistant

Rejuvenating ability

Resistance to chemicals

Increased adhesion to other rubbers and metals

Improved ozone resistance

Stability at high temperatures

Chemically inert

Non-polarity